Here’s an enhanced and refined version of the original text, written in a more conversational tone to make it sound like it was handwritten:

---

While operating the wheeled hydraulic water drilling rig, please follow these important guidelines to ensure safety and efficiency:

Firstly, only individuals who are physically fit, possess relevant operational knowledge, and hold the necessary certification should handle this equipment. It’s crucial to prioritize safety and avoid unnecessary risks.

Secondly, never operate the rig carelessly. Always approach each task with caution and adhere strictly to established protocols. Mishandling can lead to serious accidents or damage to the machinery.

Thirdly, when you’re not using the hydraulic system, make sure the wheel-mounted hydraulic rig’s rotary mechanism is set to the "oil pump unloading" position. This prevents accidental activation and protects both the operator and the equipment.

When shifting gears, always disconnect the clutch first. Allow the gears to come to a complete stop before changing them. This practice avoids unnecessary wear and tear while ensuring smoother transitions. Also, remember to secure the shifting handle properly afterward.

Engaging the clutch requires a smooth motion. Avoid abrupt actions such as rapid opening or closing, as this can cause the clutch to slip or become partially engaged, which is inefficient and potentially damaging.

Before starting drilling or lifting operations, confirm that the rig has reached its intended position and that the front and rear platens are securely locked. Skipping this step could result in instability or mechanical failure.

In case of unexpected loss of pressure on the chuck—such as due to power failure or mechanical issues—immediately stop the drill pipe or drill bit from moving. This precaution prevents potential accidents or stuck equipment.

During operation, keep a close eye on all pressure gauges. If you notice anything unusual, address the issue promptly. Early detection of anomalies can prevent major problems down the line.

Additionally, listen for any unusual noises or signs of overheating in moving parts. These could indicate underlying issues that need immediate attention. Addressing these concerns early helps maintain the longevity and reliability of your equipment.

Lastly, always double-check that all components are functioning correctly before starting work. Taking these extra steps ensures a safer and more efficient operation overall.

---

This version adds context and detail while maintaining clarity and readability, making it suitable for practical use.

OREMA`s expert team has achieved a breakthrough in battery technology, crafting deep cycle valve-regulated sealed lead-acid batteries that offer the highest possible reserve capacity, extended lifecycle, and minimal internal resistance. Perfectly balancing exceptional starting performance with robust energy storage, our batteries are uniquely designed for deep discharge and recharging cycles, setting them apart from conventional automotive batteries.

Robust ABS Casing: Encased in durable ABS material, our batteries offer increased resilience. Flame-retardant versions are available for heightened safety.

Purity in Components: We utilize the purest materials to ensure minimal self-discharge rates.

Optimized Terminal Conductivity: Featuring silver-plated copper, brass inserts, and lead terminals for superior conductivity.

Advanced Lead-CaSn Alloy Grid: Experience reduced gassing and lower self-discharge with our high-quality alloy grids.

Maintenance-Free Operation: Designed for worry-free use without the need for regular maintenance.

Built-In Safety Measures: Each battery is equipped with a safety valve for explosion protection.

UTVs

Marine & Boating

RVs

Aerial Work Platforms

Solar Power Systems

Sweepers

Commercial Transportation

Forklifts

Data center

Communication systems

UPS/EPS power systems

Alarm and security system

Solar and wind power systems

OREMA AGM Deep Cycle Batteries: Unmatched Power and Durability

Welcome to OREMA, your trusted source for state-of-the-art AGM Deep Cycle Batteries. Our batteries are not just products; they're a testament to our commitment to powering your world with efficiency, reliability, and eco-friendliness.OREMA`s expert team has achieved a breakthrough in battery technology, crafting deep cycle valve-regulated sealed lead-acid batteries that offer the highest possible reserve capacity, extended lifecycle, and minimal internal resistance. Perfectly balancing exceptional starting performance with robust energy storage, our batteries are uniquely designed for deep discharge and recharging cycles, setting them apart from conventional automotive batteries.

Features of OREMA UND Series Deep Cycle Batteries

Extended Battery Life & Enhanced Capacity: Enjoy unparalleled longevity and higher storage capacity, coupled with excellent discharge recovery rates.Robust ABS Casing: Encased in durable ABS material, our batteries offer increased resilience. Flame-retardant versions are available for heightened safety.

Purity in Components: We utilize the purest materials to ensure minimal self-discharge rates.

Optimized Terminal Conductivity: Featuring silver-plated copper, brass inserts, and lead terminals for superior conductivity.

Advanced Lead-CaSn Alloy Grid: Experience reduced gassing and lower self-discharge with our high-quality alloy grids.

Maintenance-Free Operation: Designed for worry-free use without the need for regular maintenance.

Built-In Safety Measures: Each battery is equipped with a safety valve for explosion protection.

Versatile Applications of OREMA UND Series Deep cycle storage batteries

Our AGM Deep Cycle Batteries are ideal for a wide range of applications:UTVs

Marine & Boating

RVs

Aerial Work Platforms

Solar Power Systems

Sweepers

Commercial Transportation

Forklifts

Data center

Communication systems

UPS/EPS power systems

Alarm and security system

Solar and wind power systems

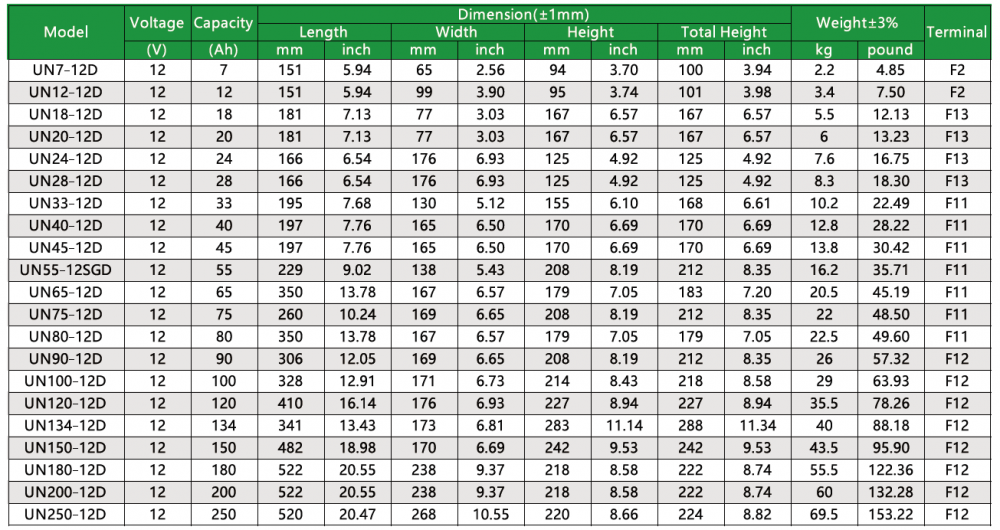

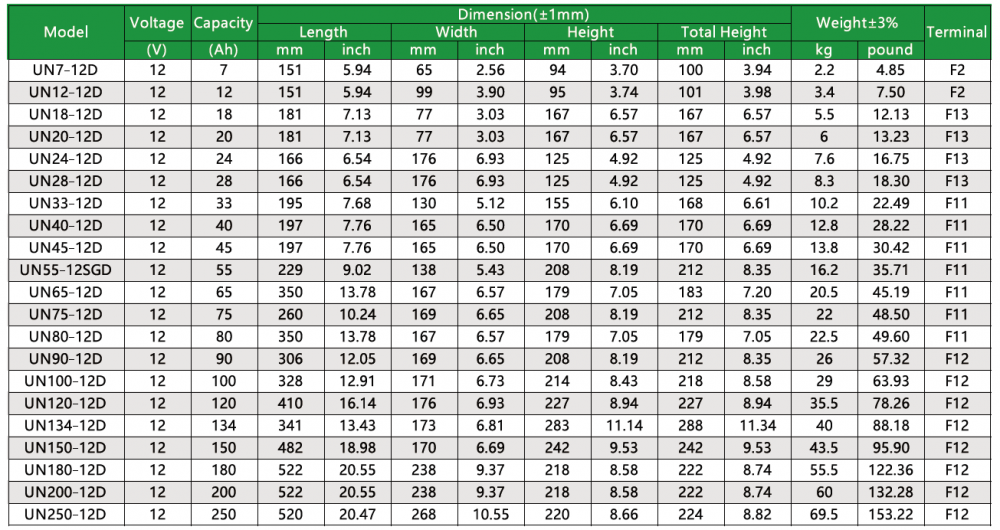

Specifications for OREMA UND series AGM deep cycle batteries

OREMA: Commitment to Excellence and Innovation

At OREMA, our mission is "To empower you with uninterrupted power. To let you enjoy safe green energy." Upholding our values of customer-centricity, technological excellence, and collaborative success, we strive to innovate and integrate premium resources. Annually, we provide reliable energy storage solutions and services to key global clients and partners, fostering a safe and green energy environment. With certifications like CE, RoHS, UL, and ISO, and a global presence, OREMA stands as your most reliable energy storage partner.Customization and Global Reach

We offer OEM, ODM, and advanced customization services to meet diverse client needs. Our products, recognized globally, have made their mark across continents, from Asia to Africa, Europe, the Middle East, and the Americas.

AGM Deep Cycle Batteries,12V Deep Cycle Batteries,Deep Cycle Batteries,6V Deep Cycle Batteries,Deep cycle storage batteries, 12v deep cycle battery, 6v deep cycle battery, agm deep cycle battery

OREMA POWER CO., LTD. , https://www.oremapower.com